Project Pathfinder

How could a crewed rocket to Mars, possibly, be designed to support

100 people on the journey to Mars?

Pathfinder // 12.15.24 – 04.25.25

From Concept to Launch

Conceptualization

Pathfinder // 12.15.24 – 04.25.25

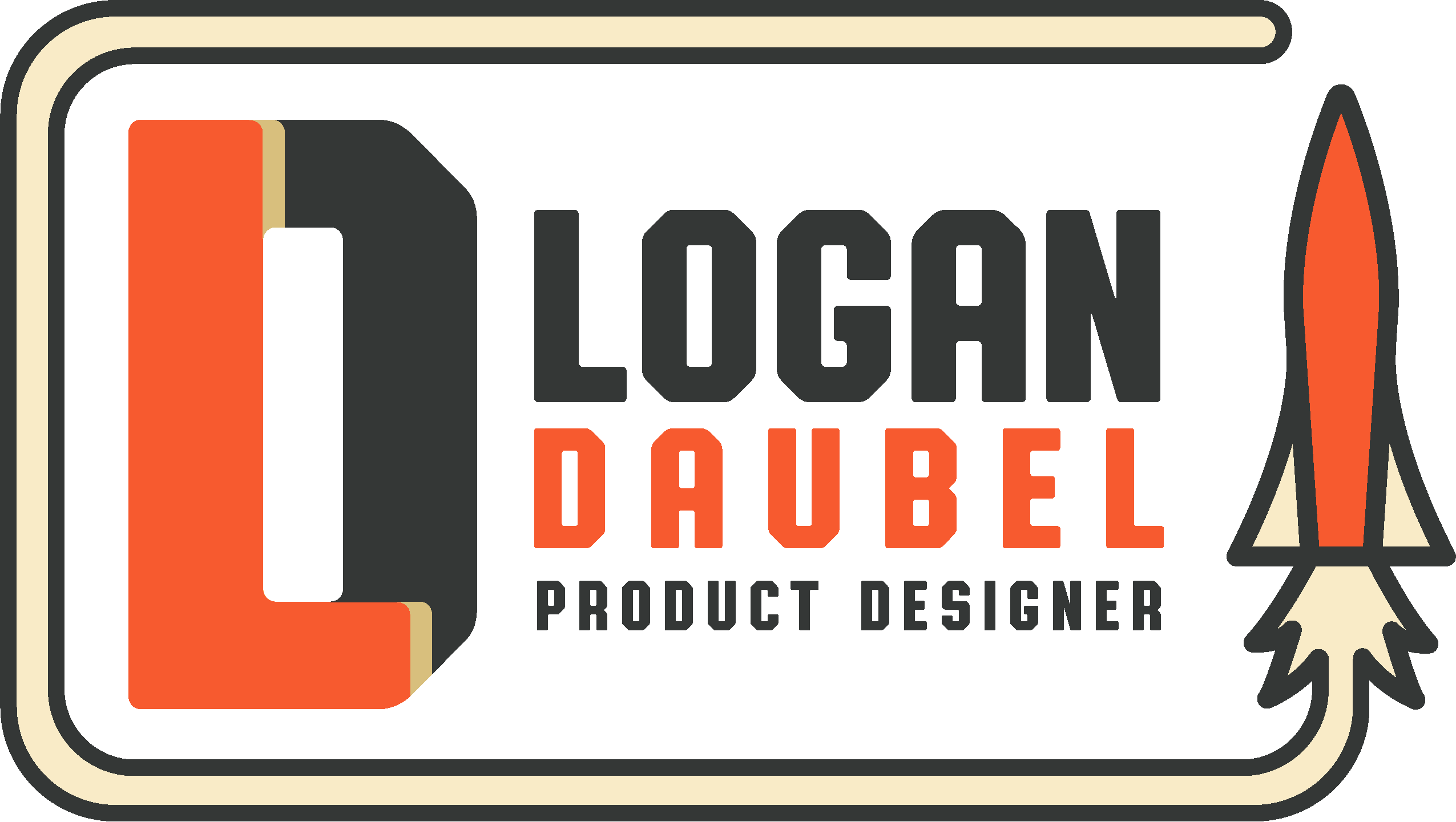

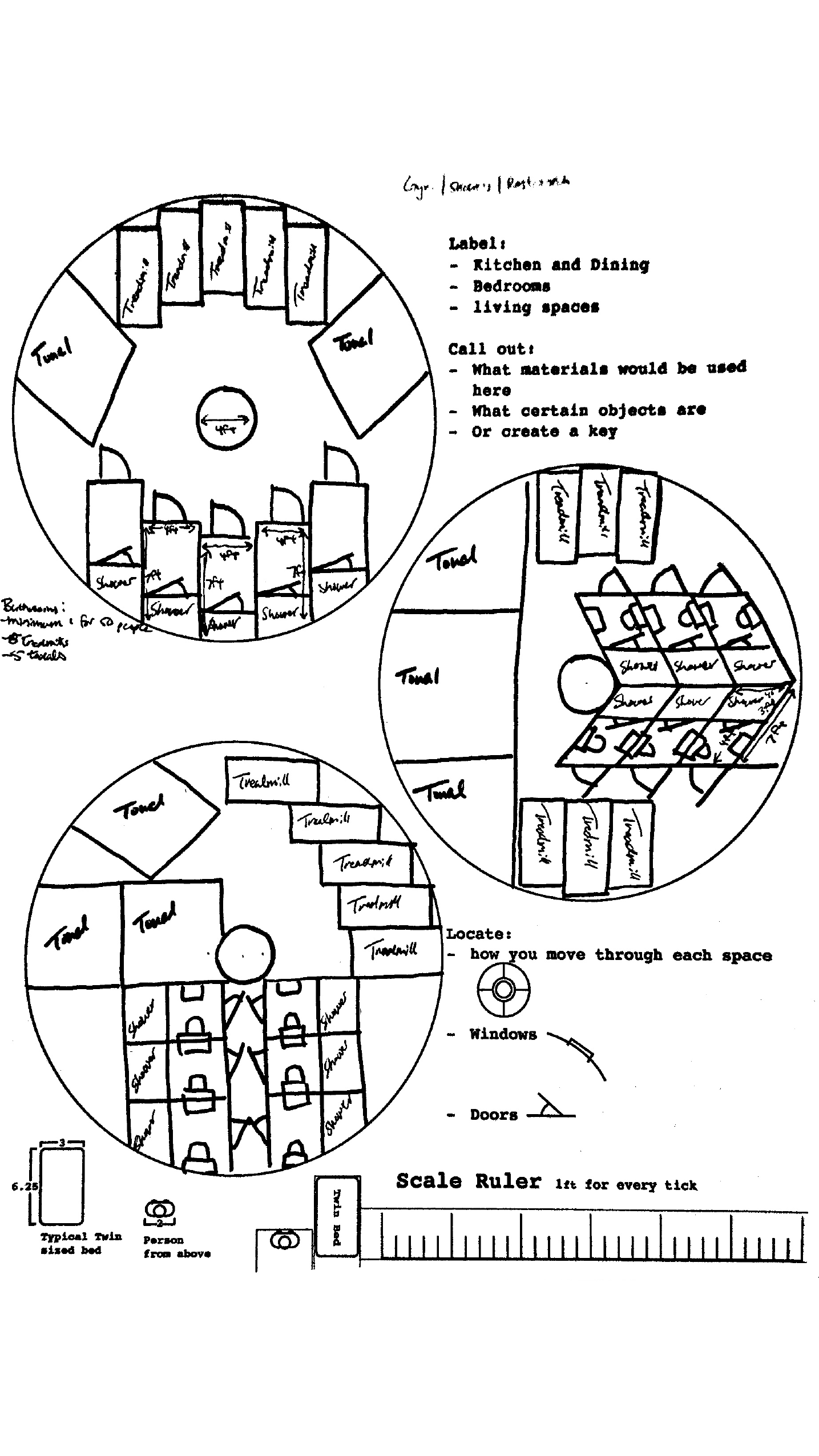

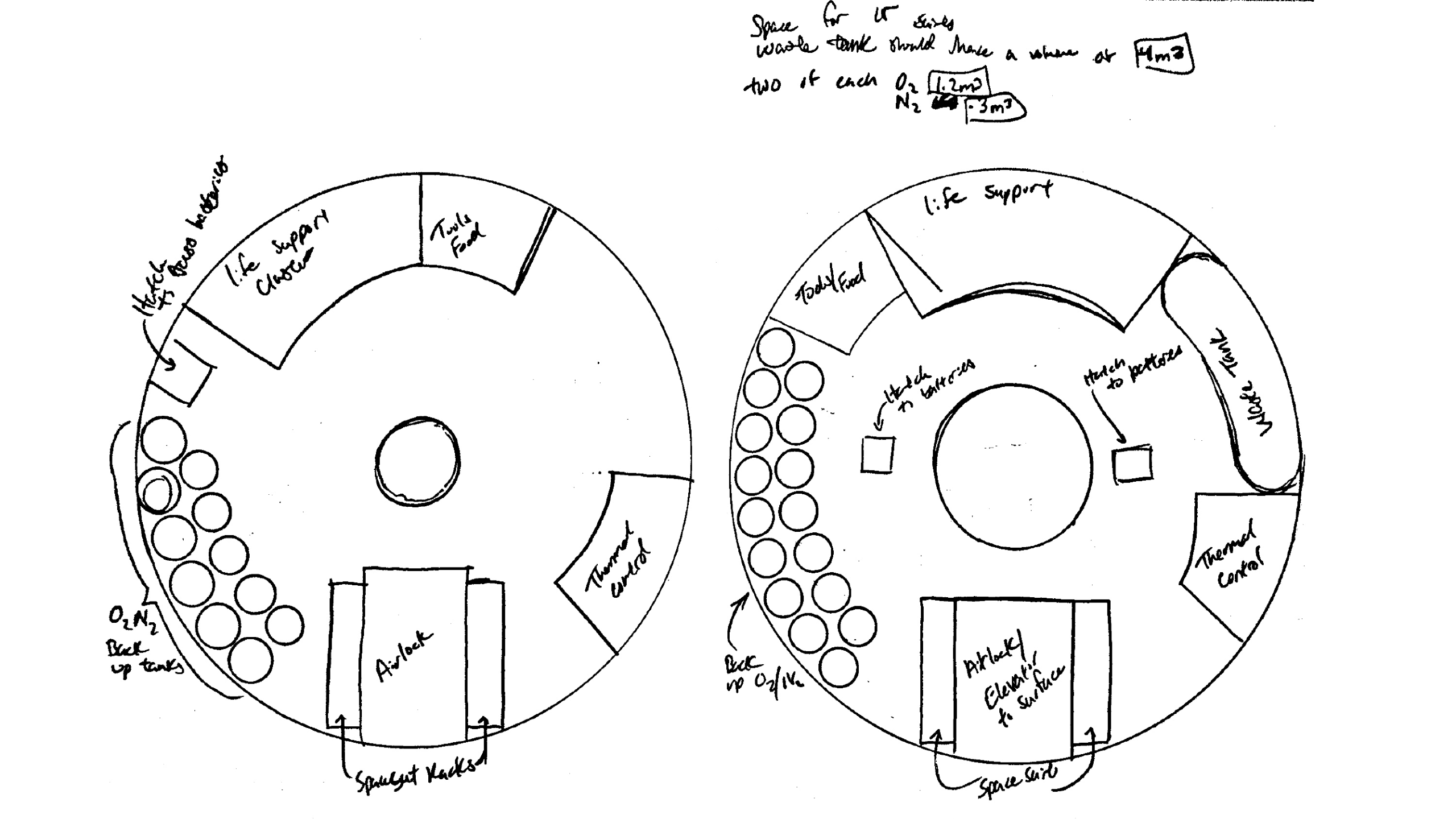

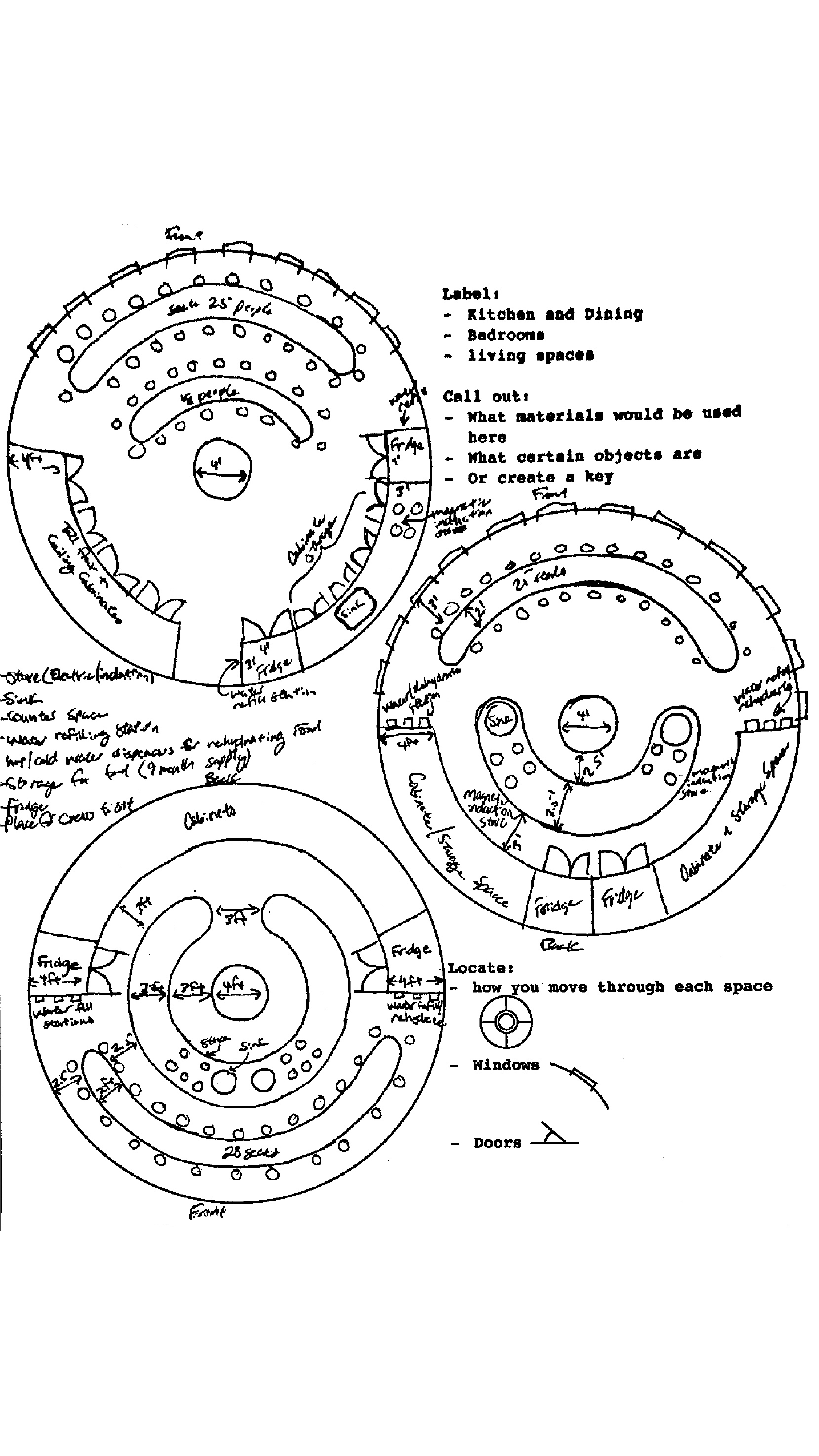

Initial research looked into the requirements for a Mars mission by studying the current systems used on the ISS and SpaceX’s Crew Dragon, focusing on life support and crew accommodations to ensure scalability for a 100 person crew on a long duration journey. This research informed my design approach, allowing me to prioritize modularity and efficient use of space within the Starship framework to support extended missions. I began with initial sketches to explore various layouts for each crew module layouts, ensuring each crew space balanced functionality, accessibility, and comfort. For example, I conceptualized multi-level crew modules with designated areas for sleeping, dining, and recreation, drawing inspiration from Crew Dragon’s compact yet efficient interior design. These early sketches also focused on the human factor aspect and laid the foundation for the parametric modeling phase, enabling me to address the unique challenges of supporting a large crew while aligning with the ambitious goals of space exploration, such as those pursued by SpaceX.

Prototype

Pathfinder // 12.15.24 – 04.25.25

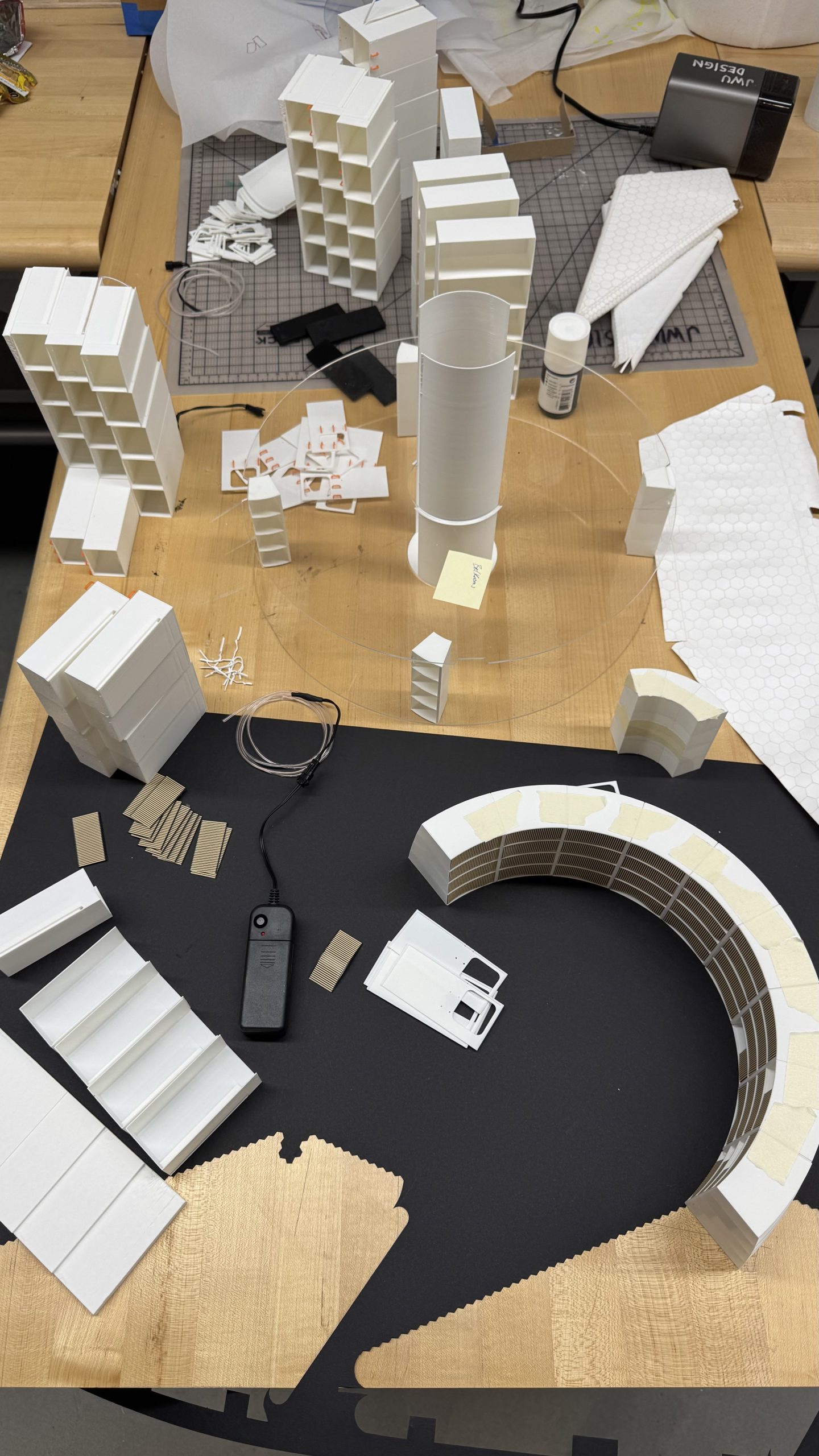

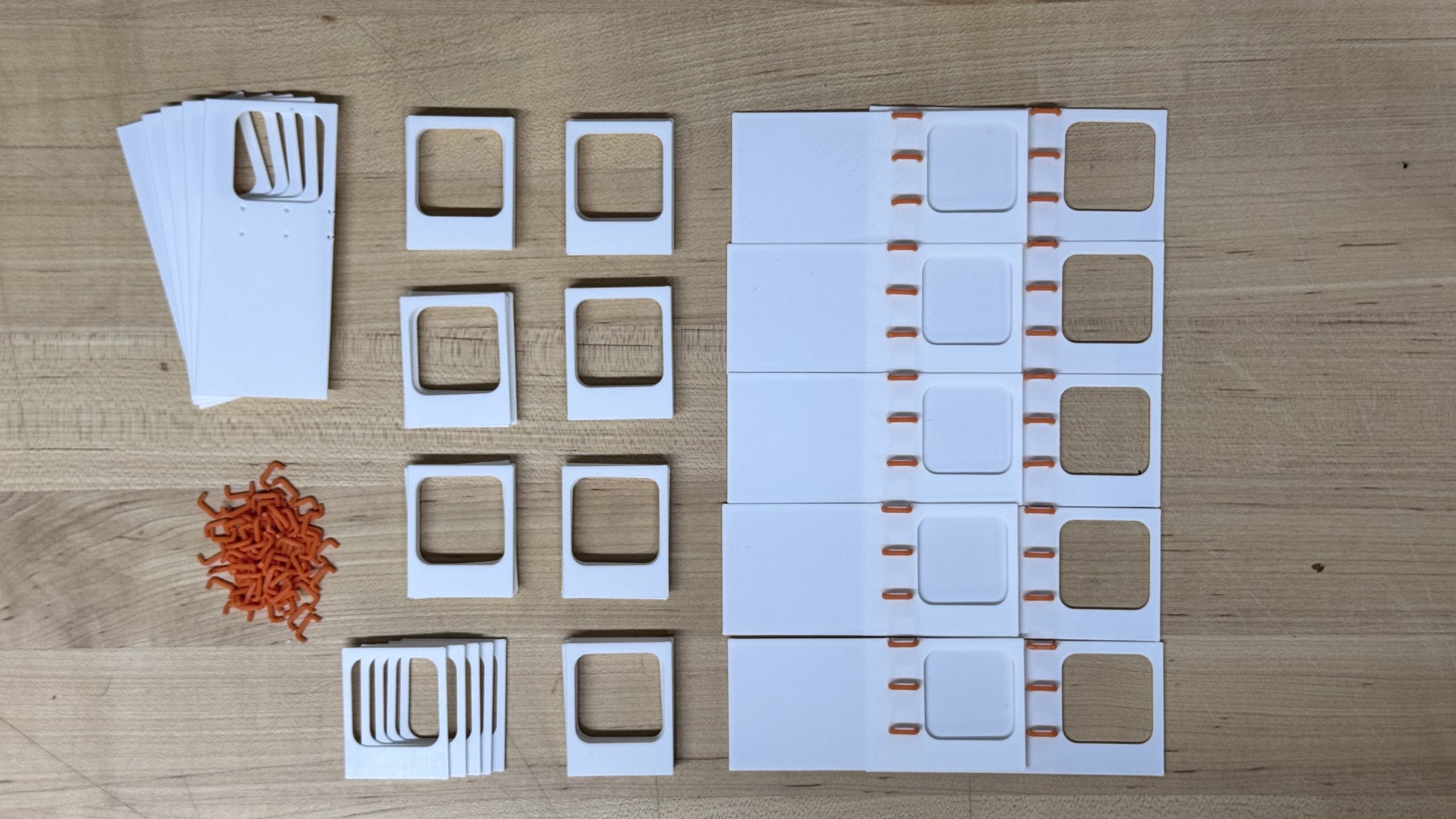

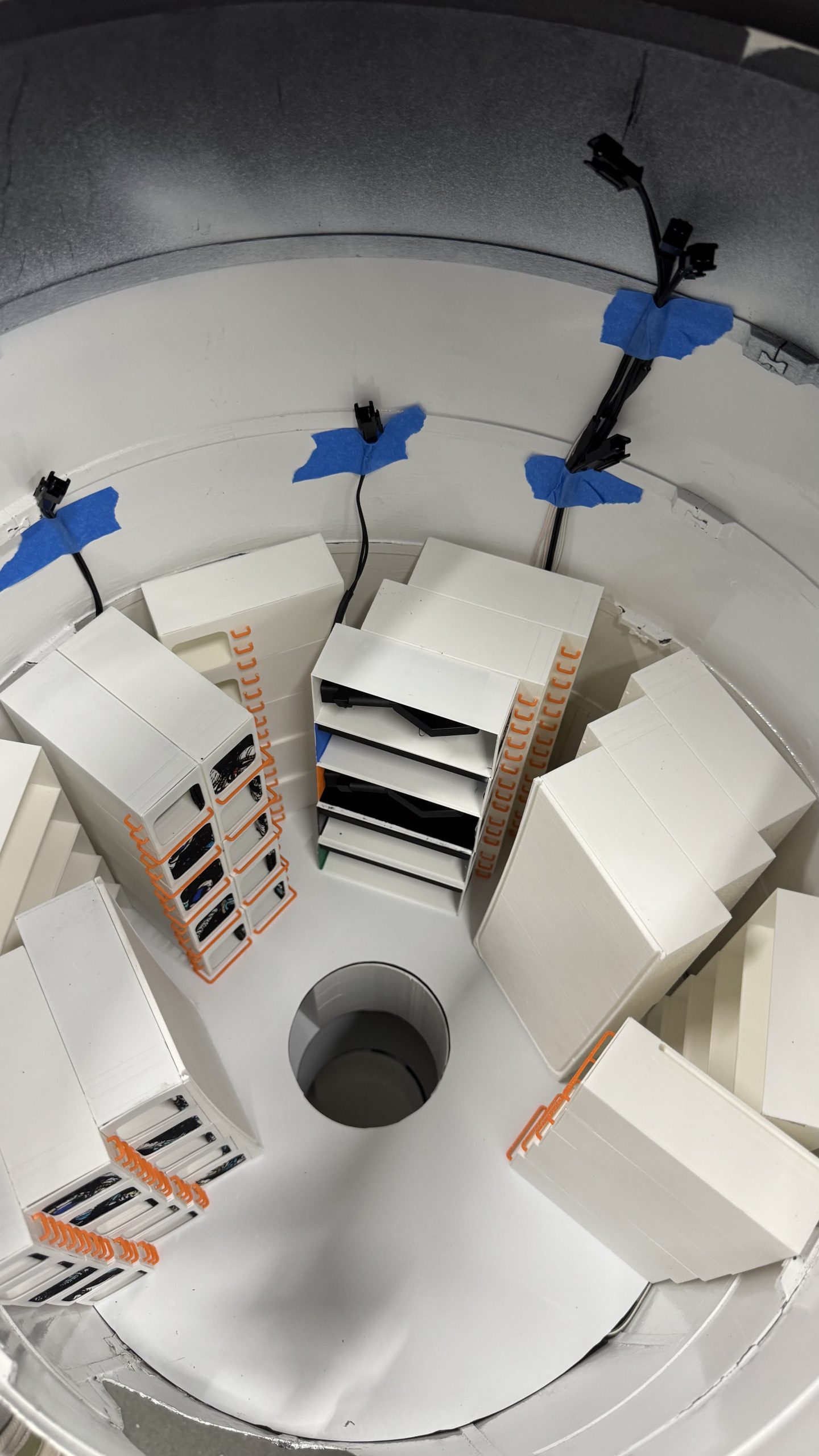

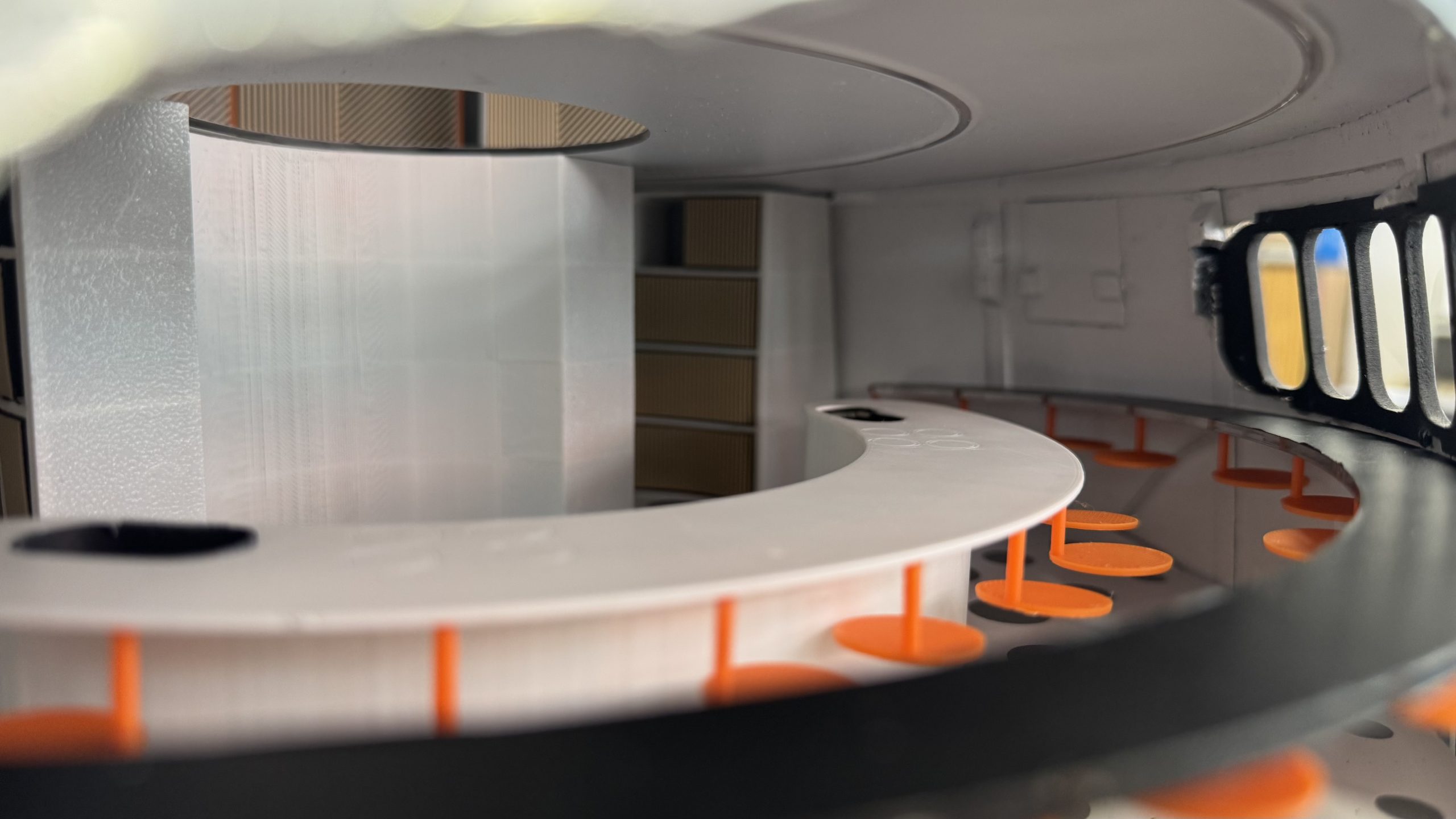

Using OnShape, I parametrically modeled both the interior and exterior of the Starship at full scale and the scaled version, allowing for precise adjustments to components like header tanks, waste tanks, and battery systems critical for mission success. This dual-scale approach enabled me to explore the ship’s overall structure, such as the airframe and nosecone, while focusing on intricate interior details, including a subfloor layout with scaled Tesla Model 3 battery packs to power systems for up to 5 days. Leveraging 3D printing, I rapidly prototyped and tested various elements, from the tank wall connection system, which used interlocking joints for structural integrity, to the sizing of individual handles placed strategically around the ship for crew mobility in microgravity. Throughout this process, I iterated designs based on test fits, ensuring components like the handles were ergonomically scaled for usability while maintaining proportional accuracy across the model. This phase highlighted my ability to combine advanced CAD tools with rapid prototyping to solve complex design challenges, preparing me for roles requiring precision and innovation in aerospace design.

InstAllation

Pathfinder // 12.15.24 – 04.25.25

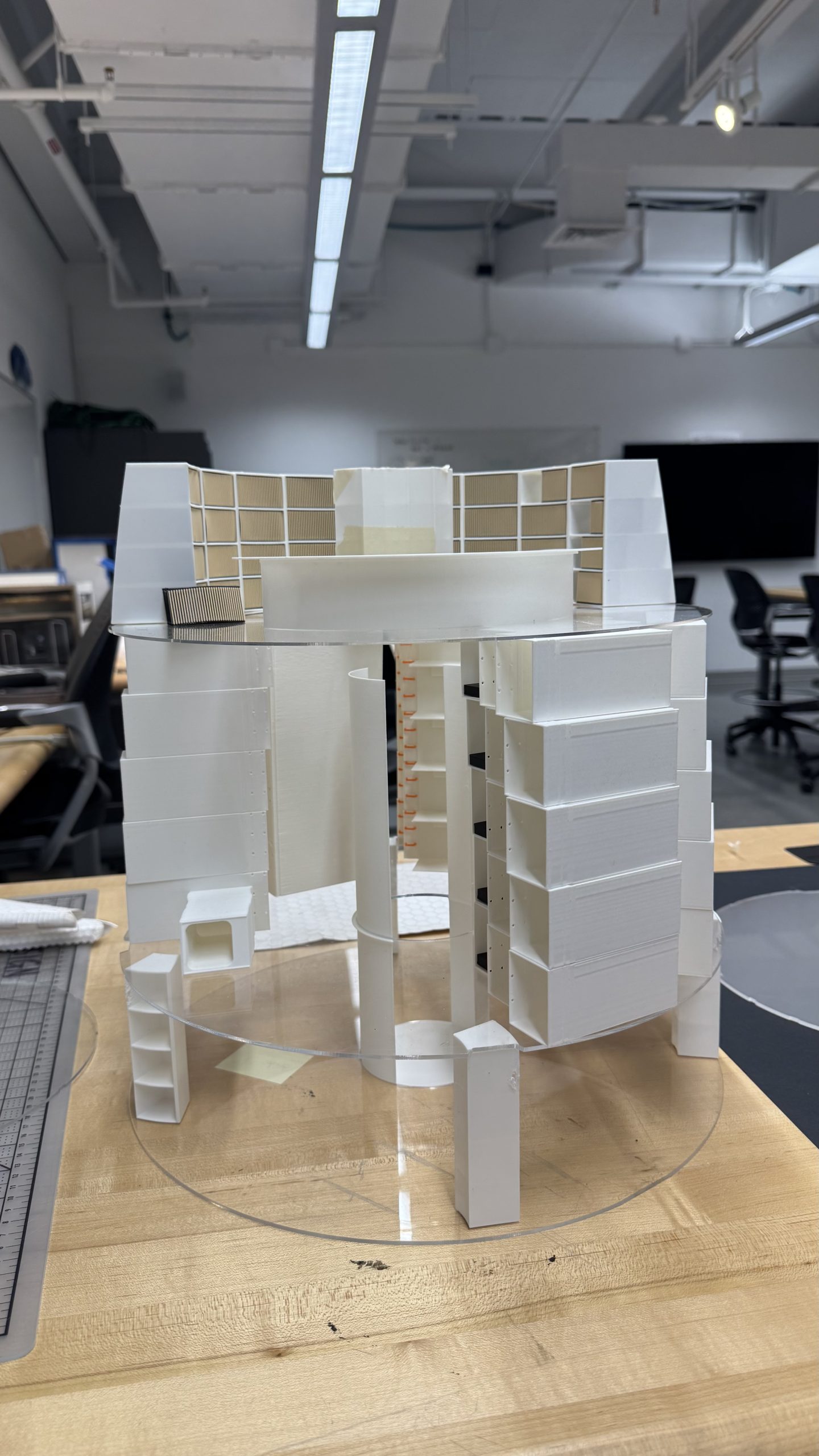

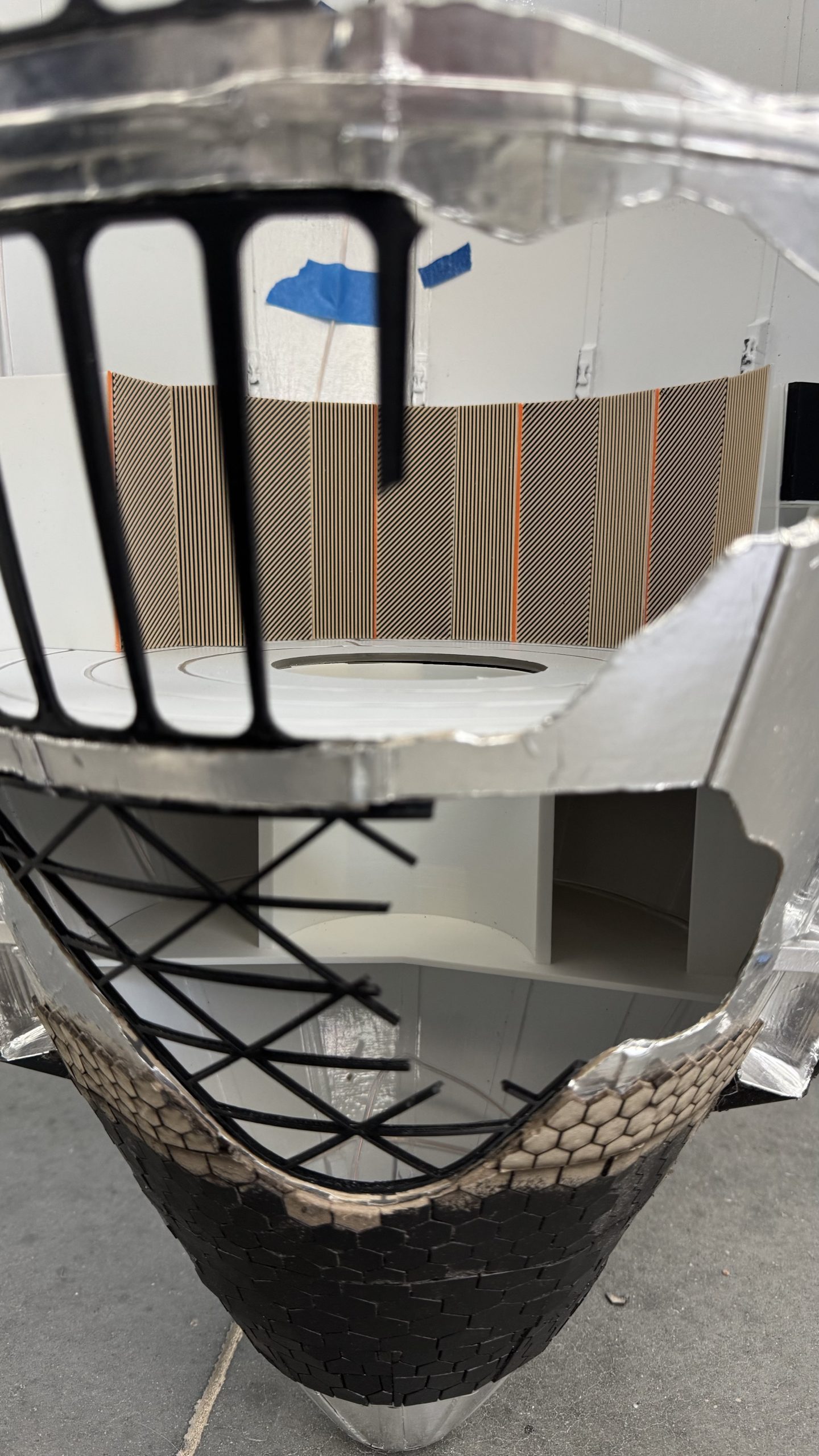

After test fitting confirmed that all components aligned correctly, I initiated mass production of the Starship model’s parts using 3D printing, focusing on scaling up while maintaining precision across the entirety of Starship. Throughout the printing process, I continuously test- fitted each component, such as the the sleeping pods within the actual nosecone to ensure the CAD model translated accurately to the physical prototype, adjusting for any discrepancies in real-time. For instance, I fine-tuned the nosecone’s interior dimensions to accommodate the subfloor layout, ensuring a seamless fit for all systems. To enhance the model’s aesthetic, I applied aluminum tape to the exterior which mimics the stainless steel finish of a real Starship while addressing minor surface imperfections. This meticulous process of simultaneous printing, test fitting, and refinement underscored my commitment to accuracy and functionality, resulting in a cohesive prototype that effectively demonstrated the feasibility of supporting a 100-person crew on a Mars mission.

Display

Pathfinder // 12.15.24 – 04.25.25

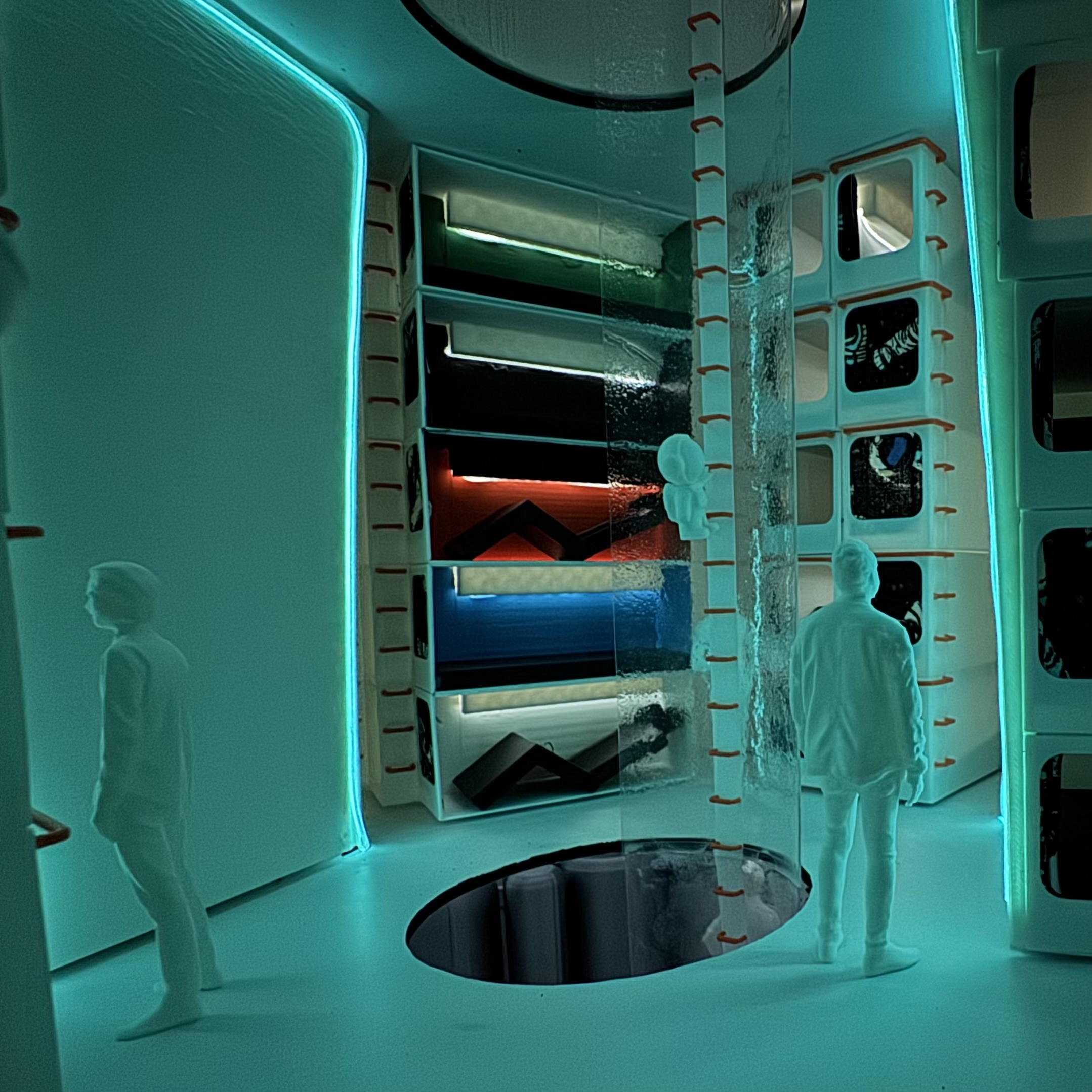

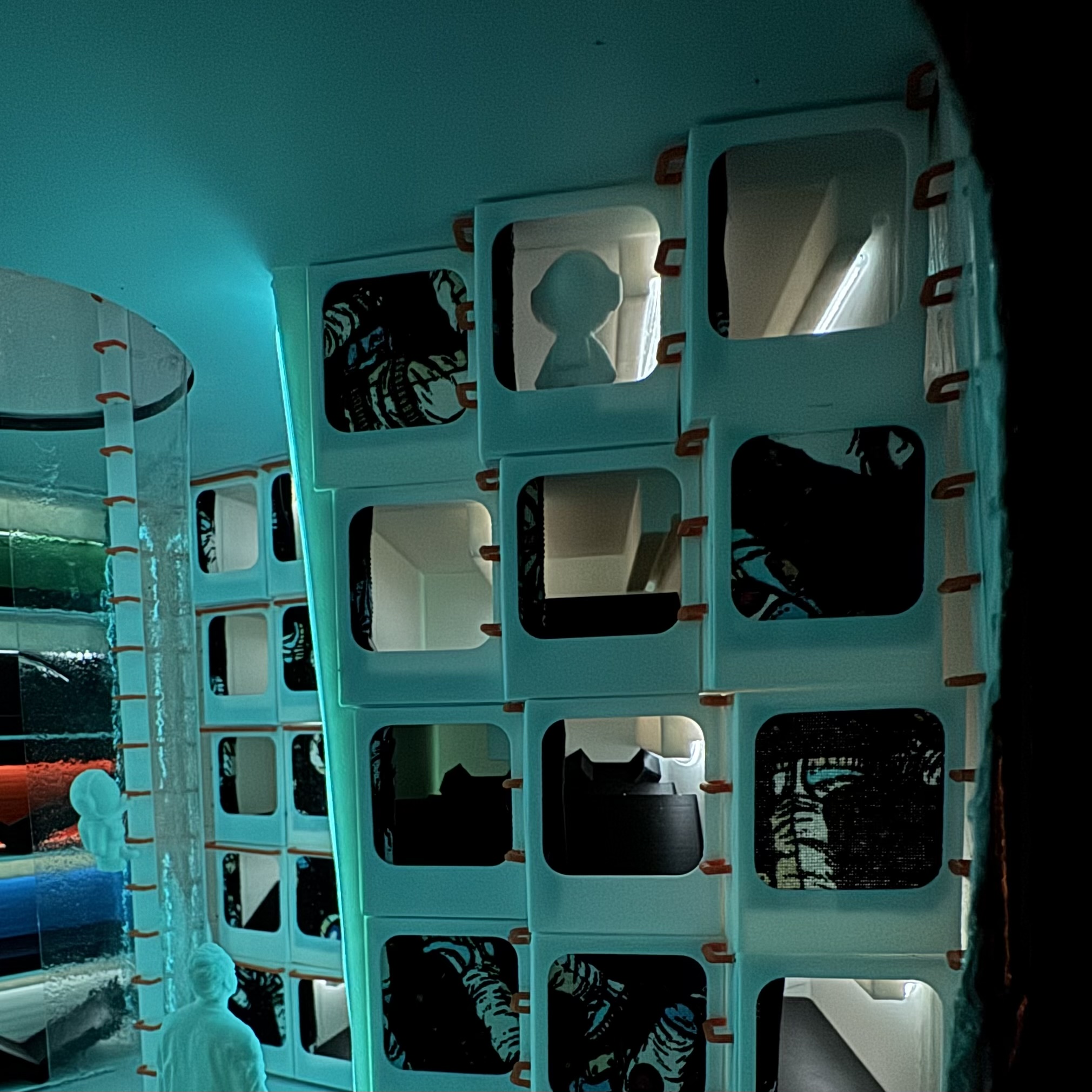

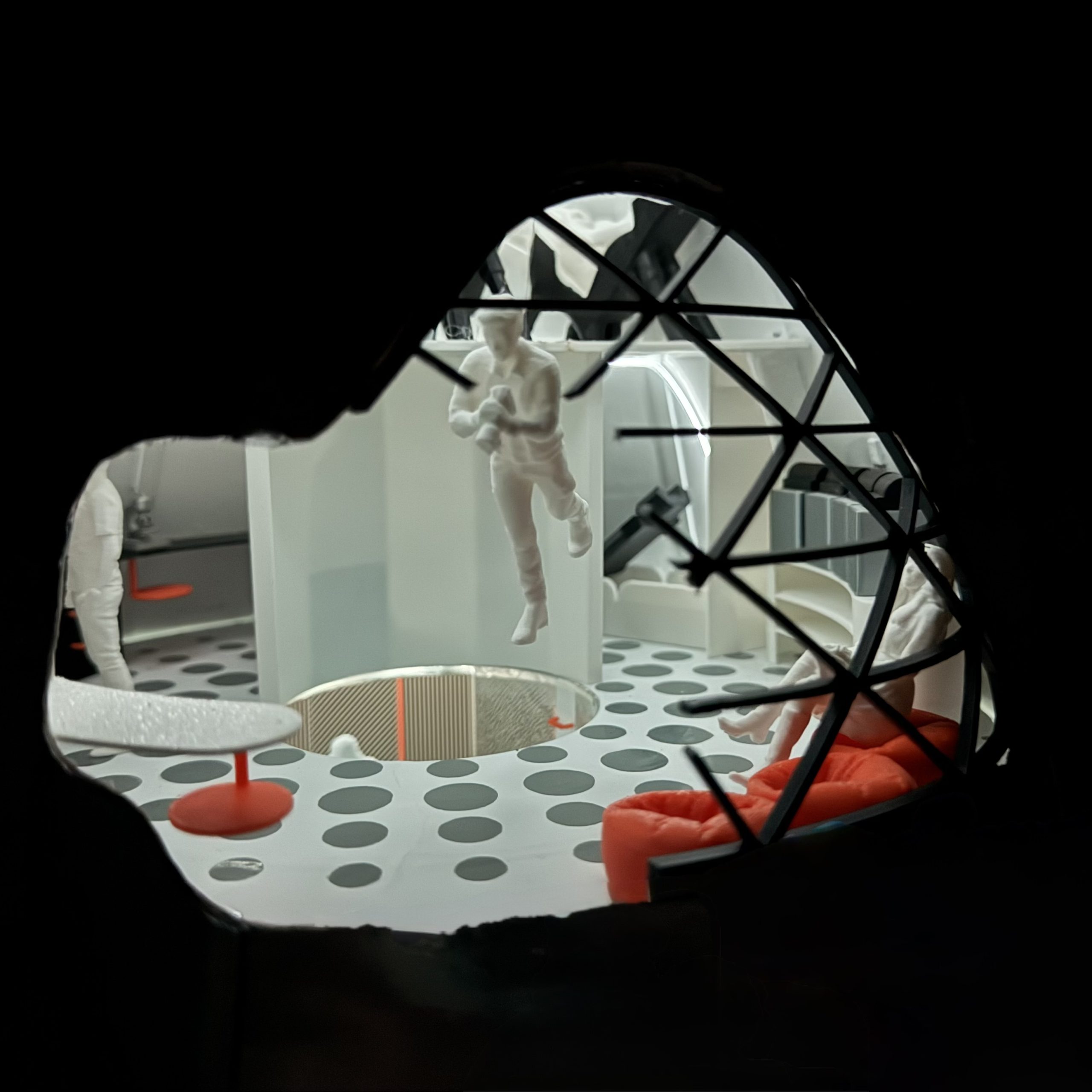

For the final installation of the Project Pathfinder Starship model, after conducting multiple test fits and iterations to ensure all components integrated together, refining the alignment of the multi-level crew modules to support a 100-person Mars journey. This phase involved installing LED lighting to each of the individual floors, wiring them to illuminate each floor and select sleeping pods, enhancing both functionality and the model’s visual impact. I also incorporated detailed floor parts such as subfloor battery compartments and adjustable bed to seating inspired by Crew Dragon, all to create a realistic and ergonomic interior layout. To provide a sense of scale, I added 3D-printed human figures, scaled to represent the crew, which helped viewers visualize the spatial dynamics. These figures were placed in areas like the dining module and control stations, bringing the model to life during my senior showcase presentation. The final installation, paired with Rhino rendered visualizations of the Mars journey, showcased my attention to detail and ability to create a cohesive, mission-ready design that balanced aesthetics with practical functionality.

launch!

Each space in all their detail

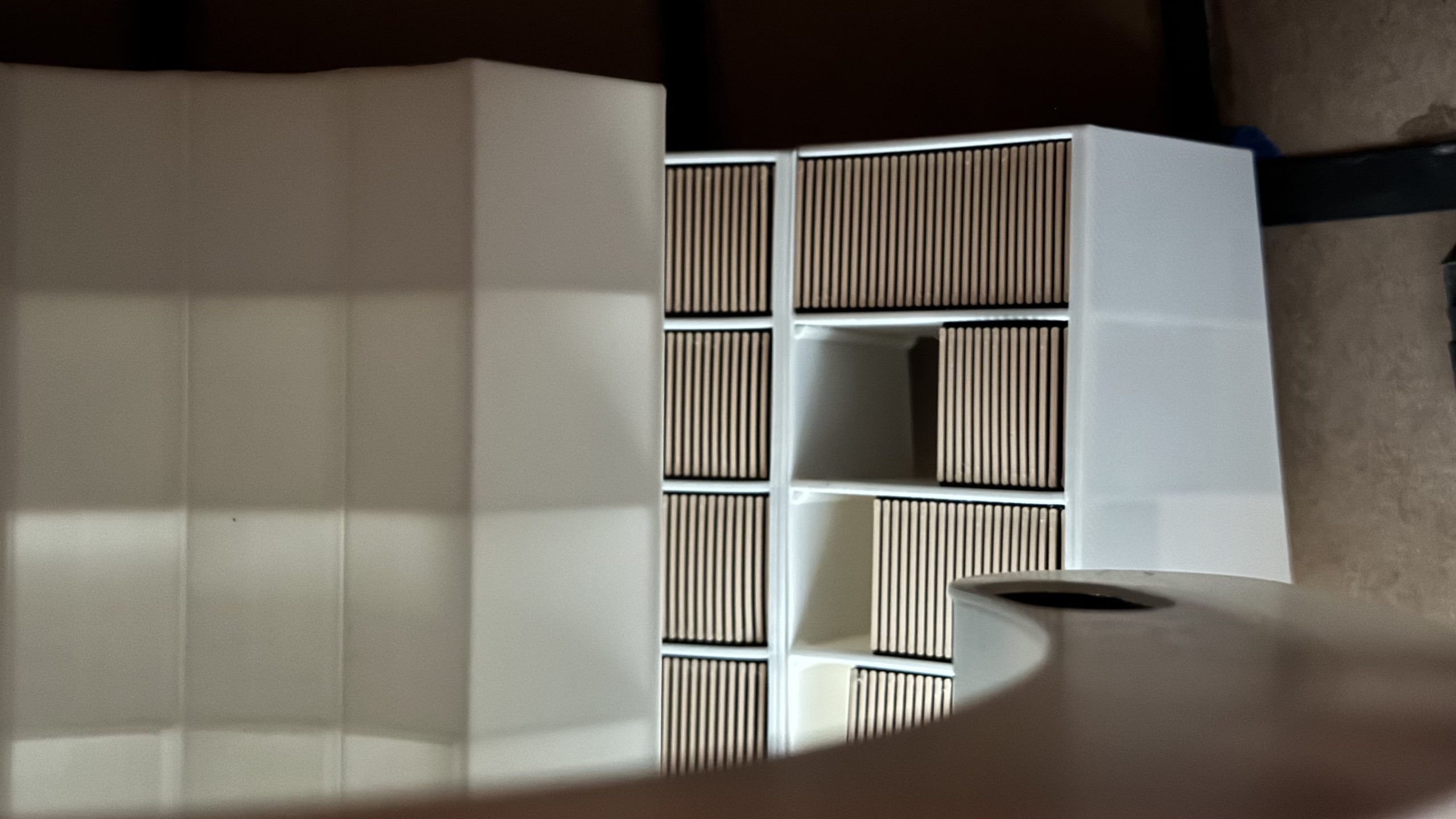

Stoage and Utilities

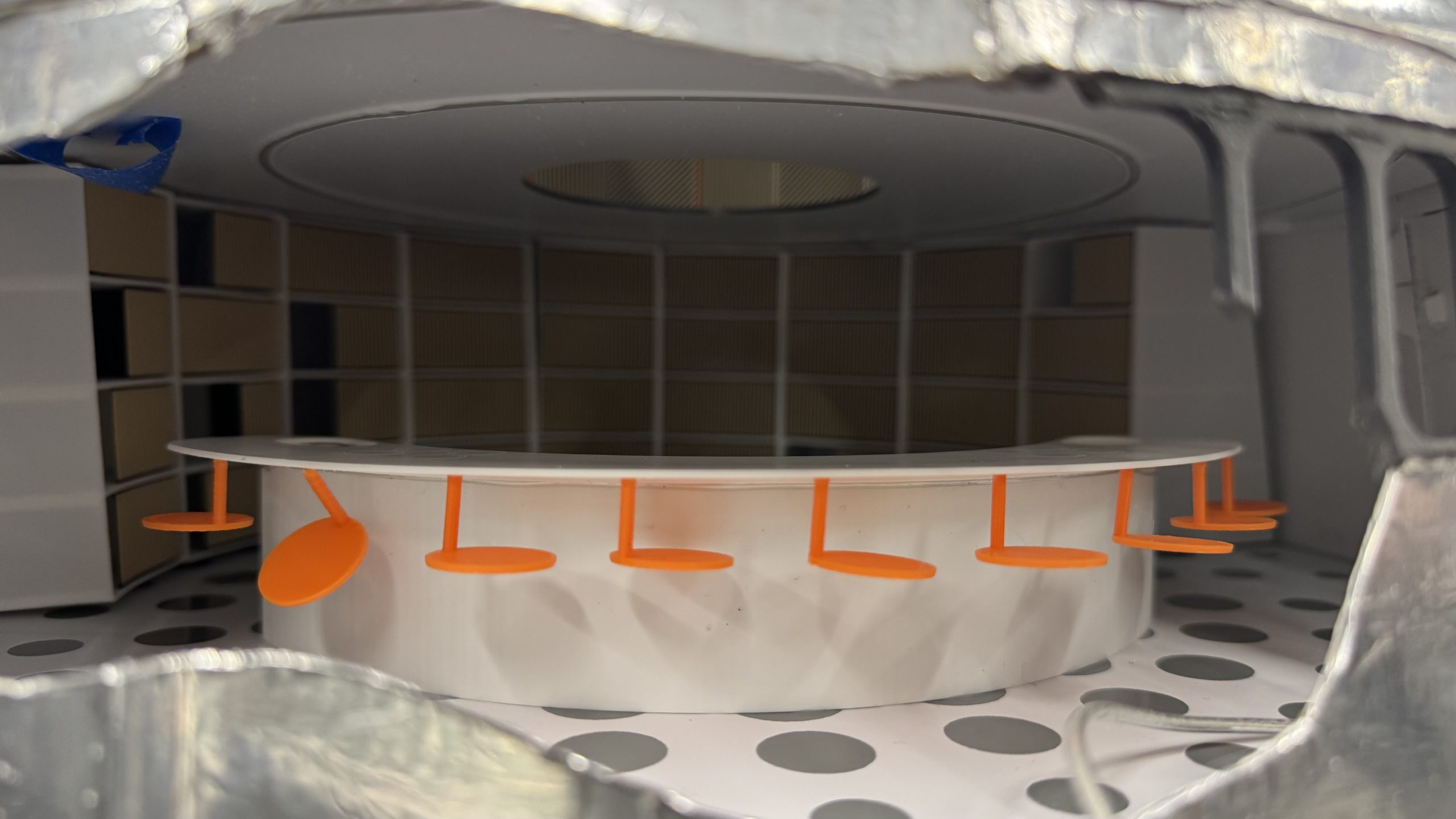

Sleeping Pods

A theme that I continued through out the project was trying to have everything serve multiple uses. The sleeping pods follow this by allowing the mattress to convert into a chair for both launch and landing.

The walls of the sleeping space are a dual wall design with water between the walls. This serves both as a water tank for the crew and also a place to go for protection against space radiation.

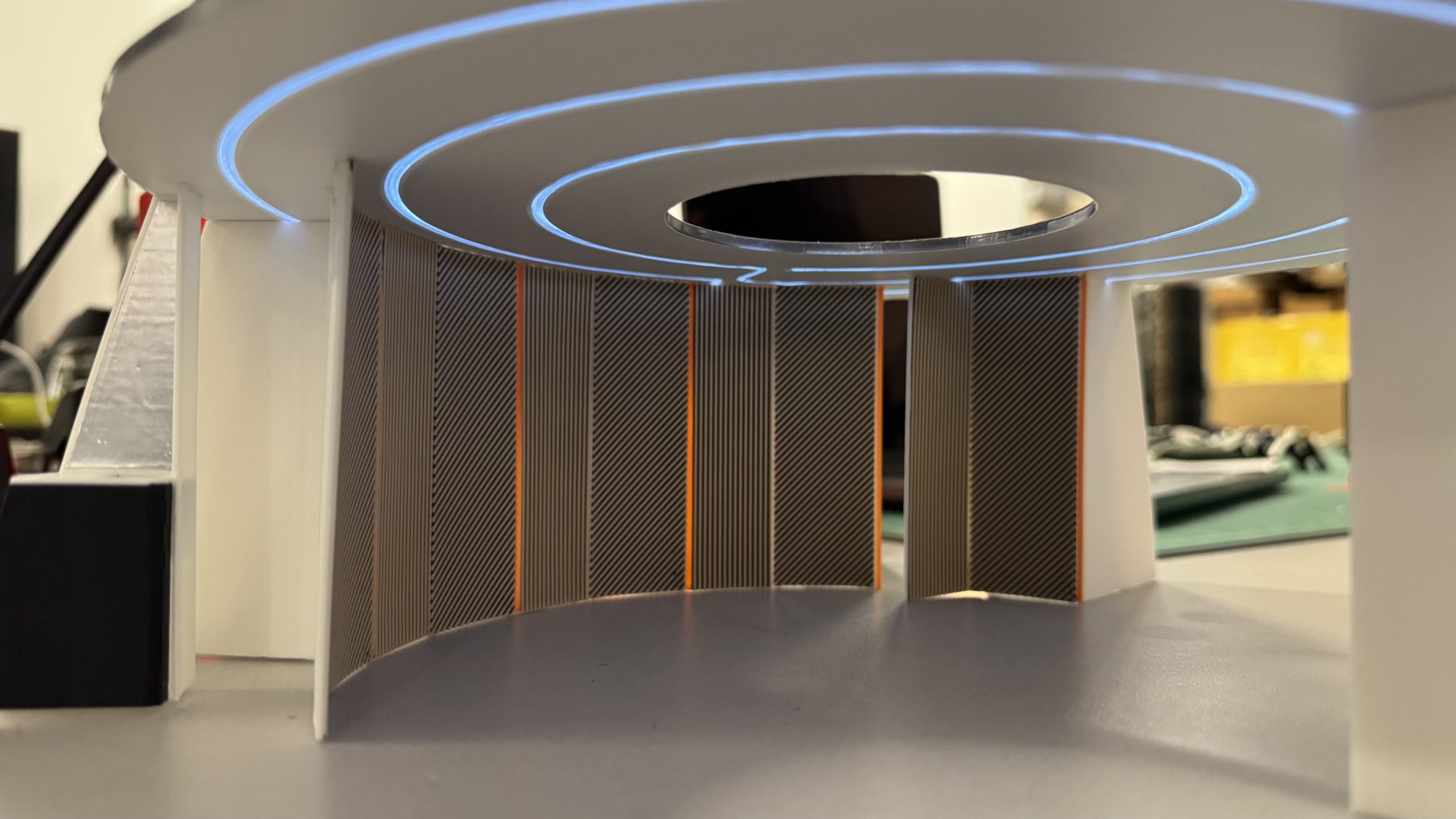

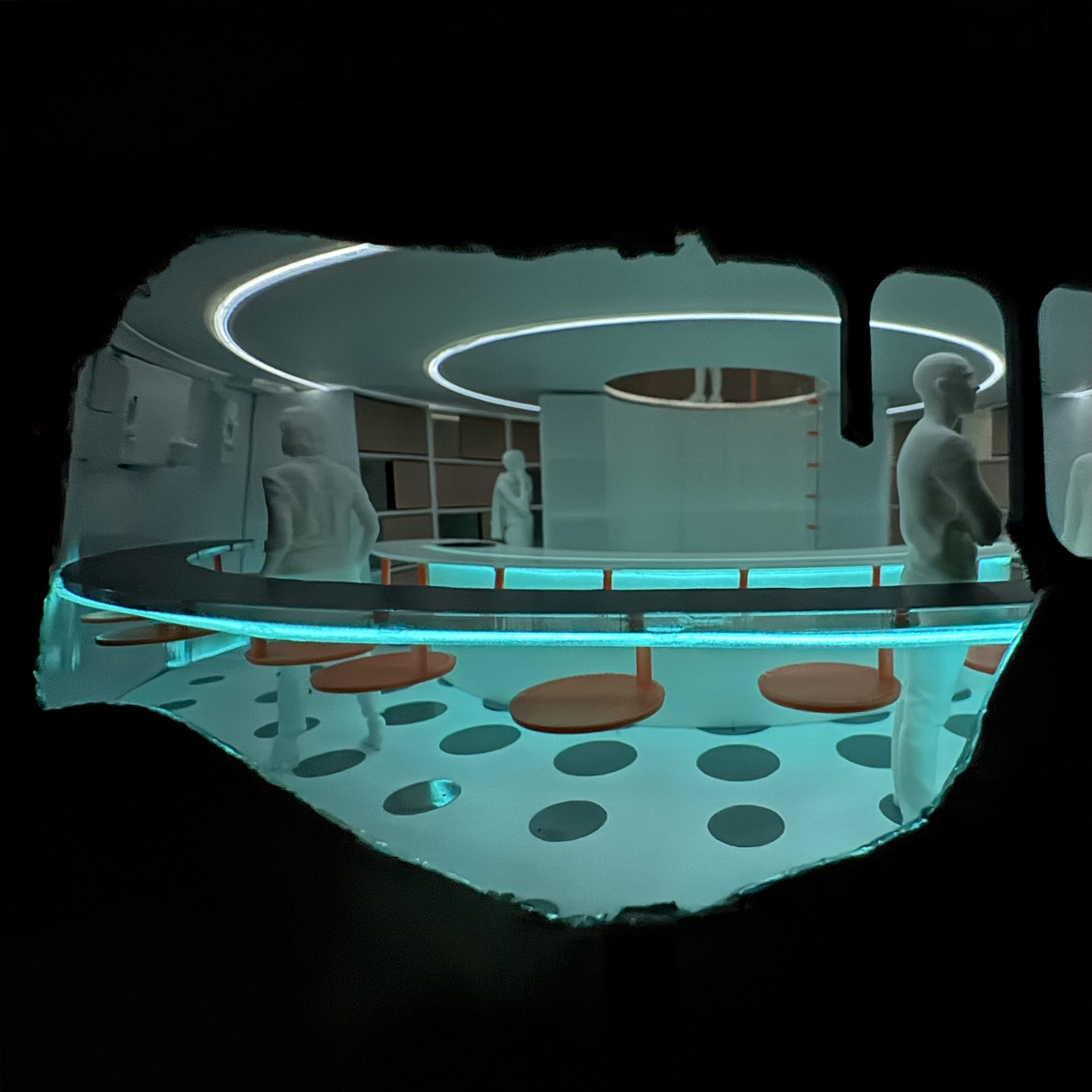

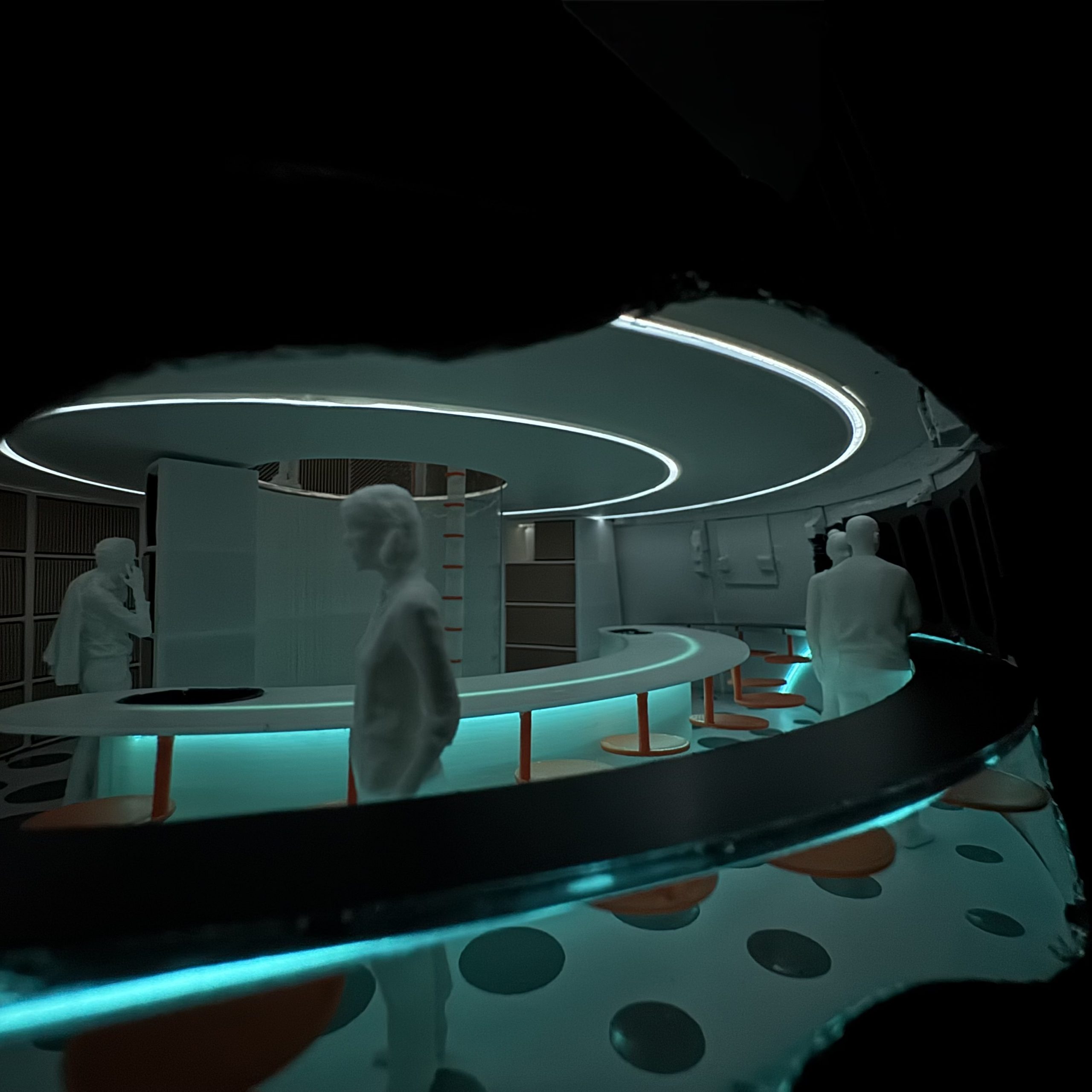

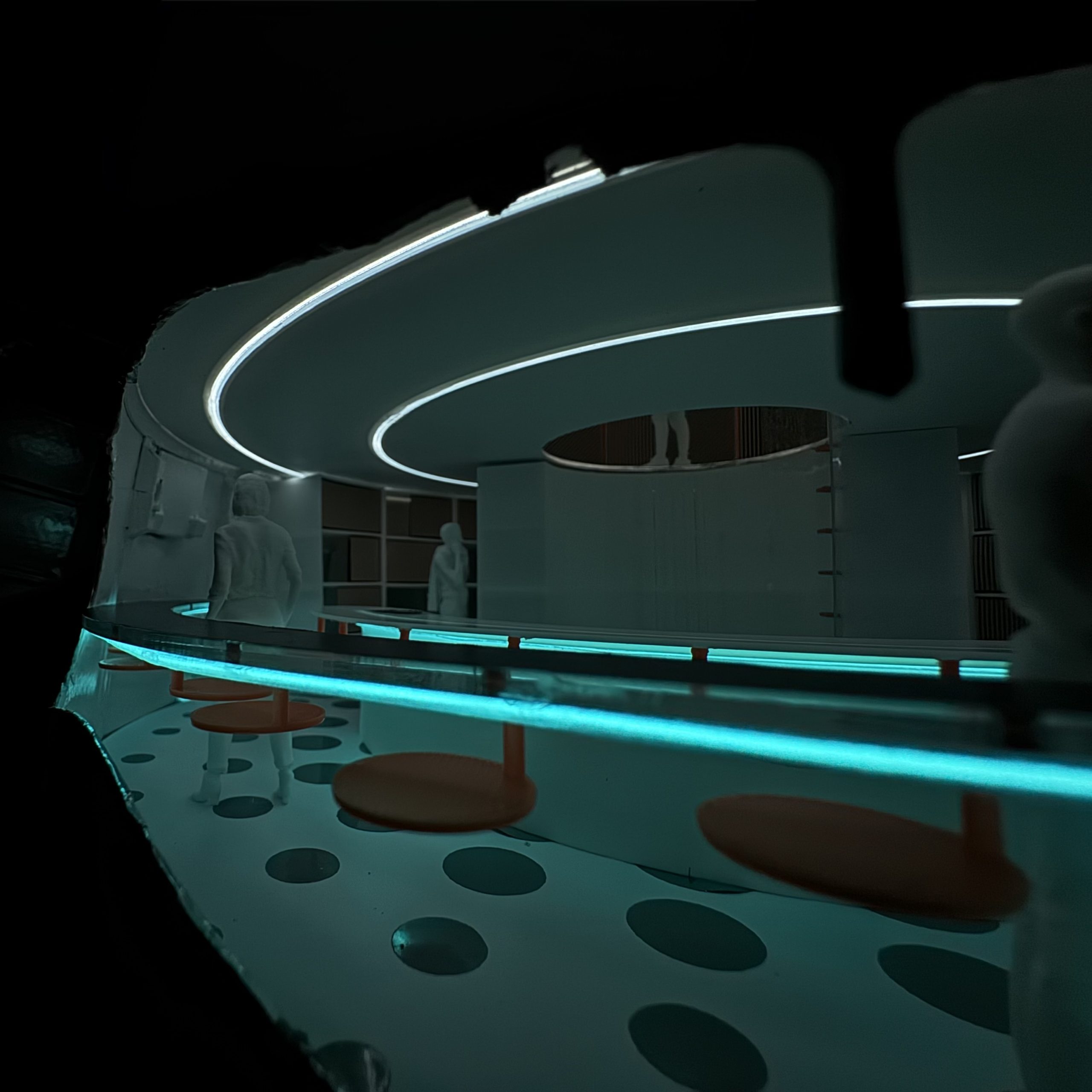

Dining Space

When designing the kitchen and dining space I set out with the intention to have this be a communal and collaborative space. Having a centered island to both cook and interact with others, the chairs are attached to the counters and swivel in and out to allow for use in both micro and full gravity. The chairs having the ability to swivel also all for communication and collaboration amongst crew members.

Gym and REstrooms

The gym is equipped with stationary bikes, treadmills, and digital resistance training equipment, keeping people healthy on their trip and ensuring there is little to no bone or muscle degradation.

The restrooms are also here, having space for 5 full bathrooms, showers toilets and all. This future proofs ship for the use of artificial gravity. Having a full bathroom also allows for a sense of normalcy for the crew.

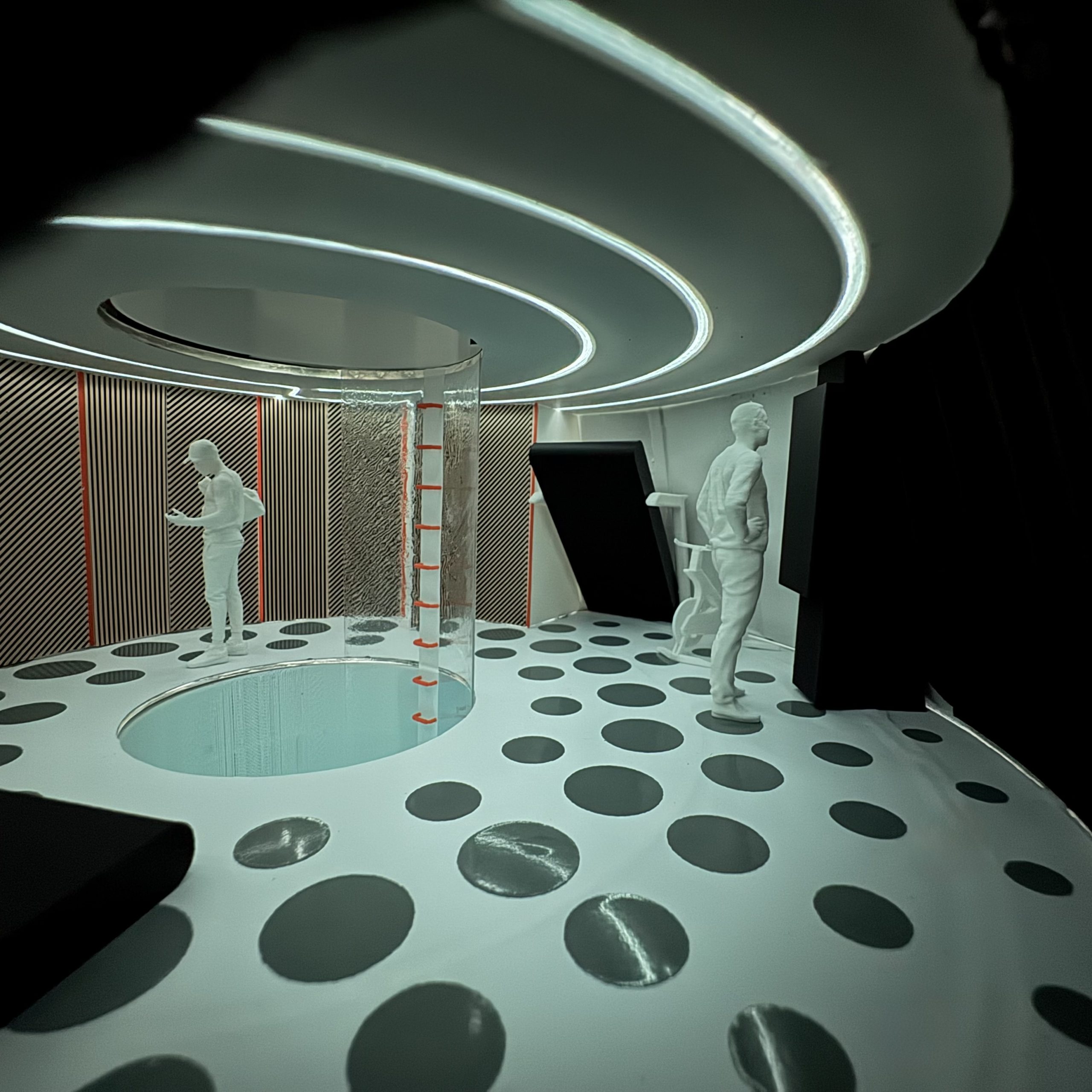

Common Space

The common space was designed to be an area for word, study, investigation, exploration, and collaboration amongst crew members. Equipped with a lab to study organisms in micro gravity and on the surface of Mars, martian regolith, and more. The medbay is also located here for anyone with any injuries or illnesses. 3D printers allow for tool making and part fixing, and something fun for crew to enjoy on their journey. The space also includes bean bags and a desk to use while enjoying a break or completing some work.

Command center is also here, controlling ship on the launch, journey and landing on Mars, ensuring everything is operating as intended.